Línea de corte longitudinal simple para perno y pista de metal

Información básica

Modelo: ZT-002

Descripción del producto

Línea de corte longitudinal simple para perno y pista de metal

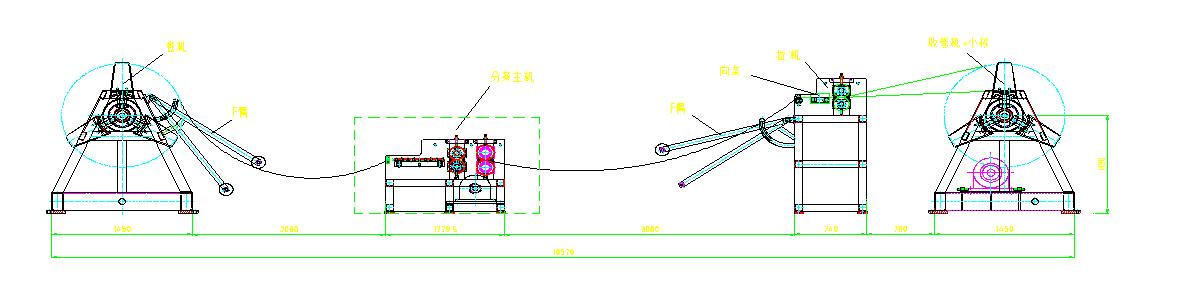

Esta máquina de corte longitudinal de metal, que diseñamos especialmente para cortar la hoja de ancho a la hoja delgada y luego hacer la pista y el perno. En términos normales, el espesor podría controlarse dentro de 0,3 a 1,0 mm. Esta es una de las imágenes de líneas de corte completo para su referencia:

Proceso de producción de línea de corte longitudinal de acero

desenrollador, dispositivo de guía, dispositivo de corte, dispositivo de corte, dispositivo de medida de longitud, dispositivo de extensión, recoiler, carro de bobina, estación hidráulica, sistema de control PLC.

Parámetros de producción:

|

Processing material: |

ALUZINC, or ALUMINIUM or STAINLESS STEAL |

|

Material thickness |

0.5-0.8mm |

|

Material hardness |

195 mpa---350 mpa |

|

Materisl width |

Max 1000 mm |

|

Inner diameter |

508mm |

|

Max out diameter |

1200mm |

|

Max weight |

Max weight: 5 T |

|

Configurations |

Decoiler, Slitting device, Cutting device, Recoiler |

||

|

Decoiler specifications

|

Max coil weight: |

5 T |

|

|

Inner diameter: |

GI 508mm |

||

|

Max out diameter |

1250mm |

||

|

Hydraulic station power: |

3 kw |

||

|

Decoiler speed: |

0-25m/min |

||

|

Finished product specifications:

|

width tolerance: |

0.5mm |

|

|

Min slitting width: |

25 mm |

||

|

Forming steps |

10 rollers |

||

|

Shaft diameter |

40mm |

||

|

Design type |

Memorial arch |

||

|

Slitting device specifications |

Slitting speed: |

0-25mm/min |

|

|

Driving motor: |

15 Kw |

||

|

Slitting shaft diameter |

Ф100mm |

||

|

Shearing blade |

9 pieces |

||

|

Max slitting pieces |

10 pieces |

||

|

Min slitting width |

25 mm |

||

|

Shearing blade material: |

9CrSi |

||

|

Pinching roller: |

2 couples |

||

|

Cutting device.

|

Cutting thickness |

0.3-1.0mm |

|

|

Cutting length |

500-4000mm |

||

|

Cutting width |

900-1250mm |

||

|

Cutting speed: |

4-15m/min |

||

|

Recoiler specifications:

|

Max coil weight: |

5 T |

|

|

Inner diameter: |

508/610mm |

||

|

Max out diameter: |

1250mm |

||

|

Recoiler motor: |

7.5Kw |

||

|

Hydraulic station power: |

3Kw |

||

|

Recoiler speed: |

0-25m/min |

||

|

|

Voltage |

220v/60hz/3ph(or as required) |

|

l equipo estándar de la máquina

|

5T decoiler |

1 set |

|

Slitting device |

1set |

|

Extension device |

1 pc |

|

5T coiler |

1 set |

|

Coil car |

1 pc |

|

Hydraulic Station |

2pcs |

|

|

|

|

Delivery Terms: - Shipment within 60 days after receipt of down payment. Payment Terms: Payment of the contract with following schedule: - 30%: The payment shall pay by T/T the downpayment to the Seller within 15 days after the signature of the Contract. The Contract then comes into effect. - 70%: The buyer shall pay to the seller 70% of total contract amount before the seller`s ship the machine to XINGANG, CHINA. Equipment Manufacturing and Inspection/Test 1. The Seller manufactures the equipment according to the relevant standards strictly and tests the equipment according to the technical documents. 2. The Buyer shall inspect and test the commodities at the Seller`s factory at the Seller informs to confirm their conformity to the Contract Specifications. If the Buyer fails to arrive on time, the Seller shall have the right to deliver the goods according to the date stipulated in the Contract. T Technical Documents The Seller shall submit the following documents in English: 1. Foundation Plan (including the arrangement of water, electricity and air etc.) 2. Arrangement Plan 3. Operation Instruction (including the structure diagrams of the equipment, operation instruction, maintenance and trouble shooting, safe rules, consumable parts list and purchased parts list) I Installation, Commissioning, Test and Training 1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning. They should start off within 10 days after they get the information from the Buyer. 2. The Seller trains the operators of the Buyer during the commissioning 3. Commissioning: about 3 engineers in 30 days. 4. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance, etc. The Buyer shall pay USD 50 /day /person to the Seller for the commissioning. 5. The Buyer shall prepare an interpreter for better communication between the two sides. |

|

Aquí hay algunas imágenes de la máquina para su referencia :

Este es el sistema de control PLC, aquí puede ajustar la velocidad de trabajo de la máquina, el proceso de corte y otros.

Este es el desenrollador, por este, puedes cargar la bobina.

Esta es una línea de corte muy simple, esta máquina es muy buena para aquellos que solo construyen la fábrica desde el principio y tienen un presupuesto reducido. Esta línea de corte es muy económica.

Grupos de Producto : Corte línea a línea de la longitud de corte